Welcome to the world of precision sawing! In this in-depth article, we delve into the realm of specialty custom saws, exploring their unique features, advantages, and applications. From hobbyists to professional craftsmen, these meticulously engineered tools empower users to tackle intricate cuts and achieve unparalleled precision. Get ready to discover the versatility, precision, and innovation that define specialty custom saws.

Contents

Introduction

Specialty custom saws are a specialized category of saws designed to meet the demanding requirements of specific cutting tasks. Unlike standard saws, which are intended for general-purpose cutting, specialty custom saws are meticulously engineered to excel in particular applications, ranging from intricate woodworking projects to specialized industrial tasks.

Their versatility extends to a wide array of materials, including wood, metal, plastic, and composites. With their exceptional accuracy and control, specialty custom saws empower users to produce precise cuts, complex shapes, and intricate designs with utmost precision and efficiency.

The key differentiator of specialty custom saws lies in their tailored configurations and advanced features. From customized blade profiles and variable speed settings to laser guides and adjustable cutting depths, these saws are meticulously designed to meet the specific demands of their intended applications.

While general-purpose saws offer a broad range of capabilities, specialty custom saws excel in specific cutting tasks, delivering unmatched precision and efficiency. Whether you’re a seasoned professional or a passionate hobbyist seeking to elevate your craftsmanship, specialty custom saws offer a gateway to a world of limitless cutting possibilities.

In this comprehensive article, we will delve into the intricacies of specialty custom saws, exploring their strengths and weaknesses, examining their technical specifications, and providing practical guidance on their selection and usage. Get ready to unlock the potential of these specialized tools and elevate your sawing skills to new heights.

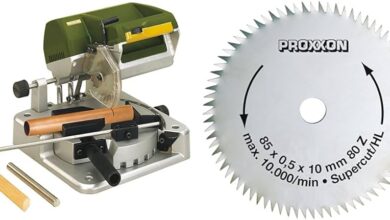

Featured Image:

Strengths of Specialty Custom Saws

Specialty custom saws possess a myriad of strengths that make them indispensable tools for demanding cutting applications. Let’s delve into the key advantages of these specialized saws:

Unmatched Precision

Specialty custom saws are engineered to deliver exceptional precision, ensuring accurate cuts and intricate designs. Their finely tuned components, precision blade guidance systems, and advanced controls empower users to achieve unmatched accuracy, even in the most challenging cutting tasks.

Whether you’re cutting delicate curves, intricate shapes, or precise angles, specialty custom saws provide the control and stability needed to produce precise cuts with minimal deviation. This exceptional precision is crucial for applications where accuracy is paramount, such as fine woodworking, model making, and precision metalworking.

Enhanced Versatility

The versatility of specialty custom saws extends beyond their ability to handle various materials. Their modular designs and customizable features allow users to tailor these saws to specific applications, ensuring optimal performance in a wide range of cutting scenarios.

From interchangeable blades and adjustable cutting depths to specialized attachments and accessories, specialty custom saws offer a level of customization that empowers users to tackle unique cutting challenges with confidence. This versatility makes them an ideal choice for professionals seeking specialized tools that can adapt to their evolving needs.

Increased Efficiency

Specialty custom saws are designed to maximize efficiency, enabling users to complete cutting tasks with greater speed and precision. Their optimized designs and advanced features reduce cutting times, minimize material waste, and streamline production processes.

By utilizing specialized blades and optimized cutting parameters, specialty custom saws can deliver clean, precise cuts with minimal effort. This increased efficiency translates into enhanced productivity, reduced labor costs, and improved overall profitability.

Weaknesses of Specialty Custom Saws

While specialty custom saws offer significant advantages, it’s important to acknowledge their potential weaknesses and limitations:

Higher Cost

Specialty custom saws are typically more expensive than standard saws due to their specialized designs, precision components, and advanced features. This higher cost can be a limiting factor for budget-conscious users or those who only require occasional cutting tasks.

However, for professionals and hobbyists who demand exceptional precision and versatility, the investment in a specialty custom saw can be justified by the enhanced capabilities and long-term value it provides.

Complex Operation

Specialty custom saws often require a higher level of skill and expertise to operate effectively. Their advanced features and precise adjustments may be daunting for novice users, requiring a learning curve before achieving optimal results.

To fully harness the potential of specialty custom saws, users are encouraged to thoroughly familiarize themselves with the operating instructions, seek professional guidance if needed, and practice on scrap materials before attempting critical cuts.

Technical Specifications of Specialty Custom Saws

To understand the capabilities and limitations of specialty custom saws, it’s essential to examine their technical specifications:

Blade Type and Size

Specialty custom saws utilize specialized blades designed for specific cutting applications. These blades vary in size, material composition, and tooth geometry to optimize performance for different materials and cutting tasks.

The choice of blade depends on the material being cut, the desired cut quality, and the specific saw model. It’s crucial to select the appropriate blade to ensure optimal results and prevent damage to the saw or the workpiece.